Analysis Na CNC Machining Case Na Aluminum Baturi Shell

Cikakken Bayani

Bukatar abokin ciniki

1. Samar da ɓangaren kamar kowane fayil na 3D kuma sarrafa daidaito tsakanin 0.05M.

2. CMM Dubawa koma zuwa haƙuri na 2D zane.

3. Tabbatar cewa taron ya yi kyau.

Binciken mu

Bayan karɓar zane-zane da buƙatun Abokin ciniki, ƙwararrun injiniyoyinmu suna da cikakken bincike da tabbatarwa cewa za mu iya samar da wannan ɓangaren sosai kuma mu sarrafa duk girman cikin haƙuri.Don tabbatar da taron ya yi kyau, mun nemi abokin ciniki ya samar da zanen Majalisar don bincika babu wani tsangwama tare da sauran abubuwan.

Fara aiki

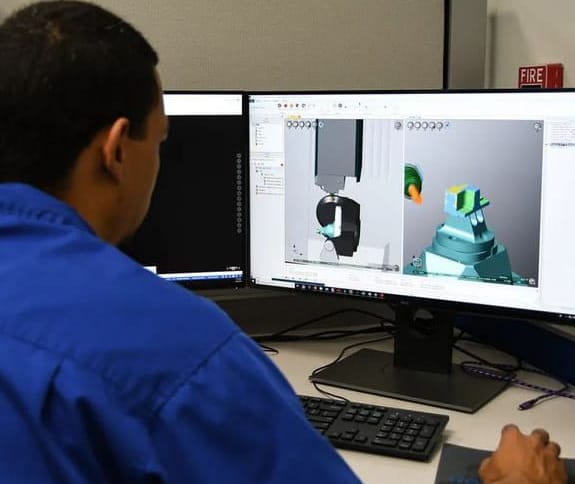

1. Shirye-shirye

Mai shirye-shiryen mu na CNC yana aiki akan saita hanyoyin aikin na'ura.

2. Injin CNC

Ana sarrafa samfurin cikin tsari kuma cikin tsari kamar yadda tsarin shirye-shiryen da muka saita.

3. Goge Hannu

Yanayin yanayi na samfurori bayan CNC yana da m kuma tare da burrs da wukake masu yawa, Ma'aikacinmu yanzu yana amfani da yashi don lalata da goge saman don samun sashi mai laushi ba tare da wani gefuna ba.Za a yi sanded ɗin daga ƙaƙƙarfan zuwa takarda mai kyau (400-1500) matakin niƙa har sai saman ya yi santsi.

4.CMM (daidaita ma'auni) dubawa

QC ɗinmu yana daidaita injin CMM don samun ingantaccen dubawa akan daidaiton girma, daidaiton matsayi, daidaiton geometric da daidaiton kwane-kwane.

5.Shiryawa

Bayan QC ɗinmu ya ba da hasken kore akan wannan samfurin, za mu fitar da su tare da fakiti mai ƙarfi don kare samfur.Don haka kowane samfurin za a isar da shi cikin yanayi mai kyau.