Saboda da high transmittance na m filastik, akwai m bukatun a kan surface ingancin filastik kayayyakin, kamar babu spots, babu alamu, porosity, whitish, gefen Lines, baki spots, discoloration, m luster, da dai sauransu Saboda haka, a cikin dukaallura gyare-gyaretsari, ya kamata a kasance masu tsauri da buƙatu na musamman don albarkatun ƙasa, kayan aiki, ƙira har ma da ƙirar samfur.

Tun da robobi na gaskiya gabaɗaya suna da babban maƙarƙashiya amma ƙarancin kwararar ruwa, daidaita ma'aunin zafin injin, matsa lamba, da saurin allura don tabbatar da ingancin saman na iya cika wurin allurar yayin da rage yuwuwar haifar da damuwa na ciki da haifar da lalacewa da fashewa.Don haka, ya kamata a aiwatar da tsauraran ayyuka a cikin shirye-shiryen albarkatun ƙasa, kayan aiki kamar fayyace kayan gyare-gyaren filastik da buƙatun ƙirar allura, aiwatar da gyare-gyaren allura da sarrafa albarkatun ƙasa.Yadda za a yi filastik mai haske a sarari?Ga wasu abubuwan da ya kamata ku sani:

1. Shirye-shiryen da bushewa na albarkatun kasa

Tun da ɗan ƙaramin ƙazanta a cikin filastik zai shafi gaskiyar samfurin, samfurin ya kamata a rufe shi da kyau yayin ajiya, sufuri da ciyarwa don tabbatar da samfurin yana da tsabta, musamman ma albarkatun ƙasa yana da sauƙin lalacewa bayan dumama.Akwai danshi kadan, don haka yakamata a bushe shi a rana.Bugu da ƙari, ana buƙatar busasshen hopper lokacin ciyarwa.Har ila yau, yakamata a tace iska mai shigowa tare da cire humided yayin aikin bushewa don tabbatar da cewa bai gurɓata albarkatun ƙasa ba.

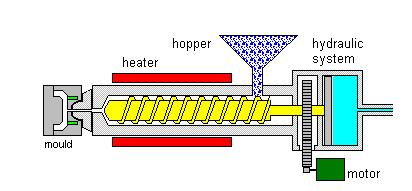

2.Cleaning na ganga, dunƙule da sauran kayan haɗi

Don hana gurɓatar albarkatun ƙasa da ɓoyayyun ɓoyayyun abubuwa ko ƙazanta a cikin wuraren ajiyar kayan na'urorin haɗi, musamman guduro tare da kwanciyar hankali na thermal mara kyau, dole ne a tsabtace filastik a kan mold da dunƙule na'ura tare da abubuwan tsaftacewa don cire ƙazanta gaba ɗaya, ko a cikin rashin ma'aikatan tsabtace dunƙule, amfani da PE, PS da sauran resins don tsaftace dunƙule.Lokacin da aka rufe ba zato ba tsammani, don hana bazuwar albarkatun ƙasa a yanayin zafi na dogon lokaci, yakamata a rage zafin na'urar bushewa da ganga, kamar PC, zafin jiki na PMMA ya zama ƙasa da digiri 160 (zazzabi zafin jiki yakamata ya zama ƙasa da digiri 160). za a rage zuwa kasa da digiri 100 PC).

3.Injection mold zane ya kamata kula da wadannan maki (ciki har da samfurin zane)

Ya kamata a lura da abubuwan da ke gaba yayin zayyana gyare-gyaren allura don hana ƙarancin gyare-gyaren filastik, lahani na saman ƙasa da tabarbarewa sakamakon rashin sake kwarara ko sanyi mara daidaituwa.

a) Kaurin bango ya kamata ya kasance mai dorewa kamar yadda zai yiwu kuma gangara daftarin ƙirar yakamata ya zama babba gwargwadon yiwuwa.

b) Canjin ya kamata ya zama mai laushi da santsi don hana kusurwoyi masu kaifi da kaifi, musamman ga samfuran pc, kuma kada a sami raguwa.

c) Gating: Mai gudu ya kasance mai faɗi da gajere gwargwadon yiwuwa, kuma wurin da ƙofar zai kasance daidai da tsarin raguwa.Ana buƙatar kayan sanyi da kyau idan ya cancanta.

d) Injection mold surface ya kamata ya zama santsi tare da low roughness (max Ra0.8)

e) Adadin ramukan huɗawa da ramukan shaye-shaye yakamata su wadatar don fitar da iska da iskar gas daga narke.

f) Kaurin bango bai kamata ya zama bakin ciki da yawa ba sai kayan PET, gabaɗaya baya ƙasa da 1mm.

Yi magana da mu game da sabon aikin ku, shawarwarin kyauta da DFM kyauta

Lokacin aikawa: Nov-01-2022