Allura gyare-gyaren surface gama kamar yadda ta SPI da VDI tsarin rarrabawa - mai sheki, Semi-mai sheki, matte da textured surface gama.

Abubuwan da ke cikin wannan labarin

Menene ƙarewar saman allura?

Injection gyare-gyaren surface gamayana da mahimmanci ga ƙirar sashi mai nasara kuma ana amfani dashi don kyawawan dalilai da dalilai na aiki a cikin sassan alluran filastik don samfuran injiniya.Ƙarshen saman yana inganta kyan gani da jin daɗin samfurin yayin da ƙimar da aka gane da ingancin samfurin ya karu tare da ƙarewar da ya dace.

Filastik Case (Source: XR USA Client)

Me yasa ake amfani da ƙarewar saman a cikin gyare-gyaren allura?

Don ƙara ƙayatarwa

Masu zanen ɓangarorin na iya amfani da laushi don dalilai na ado iri-iri.Ƙaƙwalwar shimfidar wuri mai santsi ko matte yana inganta bayyanarsa kuma ya ba shi wani bangare mai gogewa.Hakanan yana rufe kurakuran da aka ƙera ta hanyar gyare-gyaren allura, kamar alamomin injin kayan aiki, alamomin nutsewa, layin walda, layukan kwarara, da alamun inuwa.Sassan da ke da ingantaccen ingancin saman ƙasa suna jan hankalin abokan ciniki daga mahangar kasuwanci.

Don inganta aikin sashi

Baya ga kyawawan la'akari da ke cikin zaɓin ƙarewar saman allura, akwai kuma mahimman la'akari masu amfani.

Zane na iya buƙatar ƙwaƙƙwaran riko don ingantaccen aiki.Ƙarshen filastik da aka zana yana haɓaka ingancin riko.Don haka ana yawan amfani da jiyya na gyare-gyaren allura akan samfuran da ba su da ƙarfi.Samfuran da aka ƙera kuma na iya taimakawa wajen kuɓutar da iskar gas.

Ƙarshen SPI mai santsi zai iya sa fenti ya bare.Duk da haka, m surface iya tabbatar da cewa fenti manne mafi kyau ga gyare-gyaren abu.A textured SPI surface jiyya kuma yana ƙara ƙarfin sashi da aminci.

Texture yana da fa'idodi da yawa, gami da:

- Filastik kwarara creases-Waɗannan ƙuƙumman za a iya cire su ta hanyar ƙara kauri mai rubutu yayin ƙara ƙarfi da kaddarorin marasa zamewa.

- Ingantacciyar riko-Ƙara rubutu zuwa ɓangaren yana ba da sauƙin sarrafawa, ƙara amfani da aminci a takamaiman aikace-aikace.

- Paint mannewa—Paint yana manne da wani abu da aka zayyana a lokacin gyare-gyare na gaba.

- Yin undercuts- Idan kana da wani yanki wanda ba zai ci gaba da zuwa ga motsin rabin abin da ake yi ba, yin rubutu a kowane wuri na iya samar da buƙatun da ake bukata.ll.

Allura mold kayan aiki surface gama bayani dalla-dalla

Hanyar da ta fi dacewa don tantance wuraren gyare-gyaren allura ita ce ta amfani da suPIA (ko SPI), VDIkumaMold-techma'auni.Masu kera kayan aikin allura, masana'anta da injiniyoyin ƙira a duk duniya sun san waɗannan ƙa'idodi guda uku kuma matakan PIA sun fi kowa yawa kuma an fi sani da "makin SPI".

Ƙarshe mai sheki - Grade A - Ƙarshen lu'u-lu'u

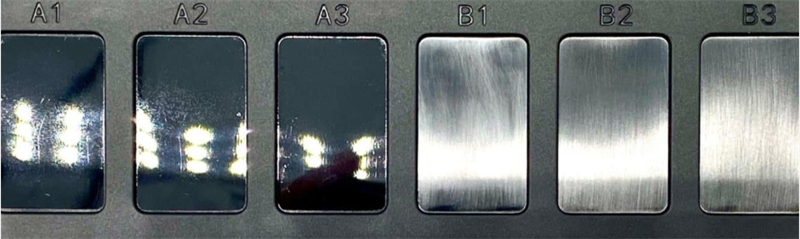

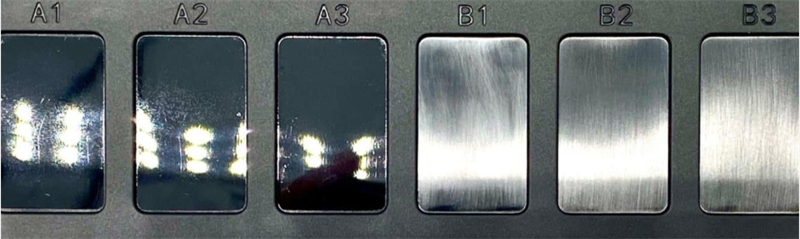

(SPI-AB Injection-moulding surface gama)

Waɗannan ƙarewar "A" suna da santsi, mai sheki, kuma mafi tsada.Waɗannan maki za su buƙaci ƙera kayan aiki na ƙarfe, waɗanda aka buff ɗin ta amfani da nau'ikan lu'u-lu'u iri-iri.Saboda manne mai kyau-buffing da hanyar bazuwar hanyar jujjuyawar polishing, ba zai sami tsayayyen rubutu da watsa hasken haske ba, yana ba da kyakkyawan ƙarewa.Ana kuma kiran waɗannan “Diamond finish” ko “buff finish” ko “A finish”

| Gama | SPI Standard | Hanyar Ƙarshe | Ƙarfin Sama (Ra Value) |

| Ƙarshen Ƙarshe Mai Girma | A1 | 6000 Grit lu'u-lu'u buff | 0.012 To 0.025 |

| Maɗaukakin Ƙarshe | A2 | 3000 Grit lu'u-lu'u buff | 0.025 To 0.05 |

| Ƙarshe mai sheki na al'ada | A3 | 1200 Grit lu'u-lu'u buff | 0.05 zuwa o.1 |

SPI mai sheki maki sun dace da samfurori tare da ƙarewar ƙasa mai santsi don dalilai na kwaskwarima da aiki.Alal misali, A2 shine mafi yawan lu'u-lu'u na lu'u-lu'u da aka yi amfani da su a cikin masana'antu, wanda ya haifar da kyawawan sassa masu kyau na gani tare da saki mai kyau.Bugu da ƙari, ana amfani da kammala saman "A" akan sassa na gani kamar ruwan tabarau, madubai, da masu gani.

Ƙarshen Semi-mai sheki - Grade B

(Figure 2.SPI-AB Allura-moulding surface gama)

Waɗannan ɓangarorin masu sheki suna da kyau don cire machining, gyare-gyare, da alamun kayan aiki tare da ƙimar kayan aiki mai ma'ana.Ana samar da waɗannan ƙarewar saman ta amfani da matakan yashi daban-daban waɗanda aka yi amfani da su tare da motsi na madaidaiciya, suna ba da tsarin layi kamar yadda aka nuna a adadi 2.

| Gama | SPI Standard | Hanyar Ƙarshe | Ƙarfin Sama (Ra Value) |

| Fine Semi mai sheki Ƙarshe | B1 | 600 Grit Paper | 0.05 zuwa 0.1 |

| Matsakaici Semi mai sheki Ƙarshe | B2 | 400 Grit Paper | 0.1 zuwa 0.15 |

| Al'ada emi Glossy Gama | B3 | 320 Grit Paper | 0.28 zuwa o.32 |

SPI (B 1-3) Ƙarfafawar saman mai sheki mai ƙyalƙyali zai ba da kyakkyawar bayyanar gani da cire alamun kayan aikin ƙira.Ana amfani da waɗannan sau da yawa a cikin sassan da ba kayan ado ba ko mahimmancin gani na samfur.

Matte gama - Grade C

Waɗannan su ne mafi ƙarancin tattalin arziƙi da mashahurin ƙarewa, gogewa ta amfani da foda mai kyau na dutse.Wani lokaci ana kiran dutsen ƙarewa, yana ba da kyauta mai kyau kuma yana taimakawa ɓoye alamun mashin.Grade C kuma shine matakin farko na kammala maki A da B.

| Gama | SPI Standard | Hanyar Ƙarshe | Ƙarfin Sama (Ra Value) |

| Matsakaici Matte Ƙarshe | C1 | 600 Grit Stone | 0.35 zuwa 0.4 |

| Matsakaici Matte Ƙarshe | C2 | 400 Grit Paper | 0.45 zuwa 0.55 |

| Al'ada Matte Gama | C3 | 320 Grit Paper | 0.63 zuwa 0.70 |

Ƙarshen rubutu - Grade D

Yana ba sashin kyakkyawan bayyanar gani na kyan gani kuma ana amfani dashi ko'ina a sassan masana'antu da kayan masarufi.Waɗannan sun dace da sassa ba tare da takamaiman buƙatun gani ba.

| Gama | SPI Standard | Hanyar Ƙarshe | Ƙarfin Sama (Ra Value) |

| Satin Texture Gama | D1 | Dutse 600 kafin busassun busassun gilashin dutse #11 | 0.8 zuwa 1.0 |

| Dry Texture Gama | D2 | Dutse 400 kafin busasshen busasshen gilashin #240 oxide | 1.0 zuwa 2.8 |

| M Texture Gama | D3 | 320 dutse kafin busassun fashewa #24 oxide | 3.2 zuwa 18.0 |

Babu wanda ya taɓa cewa ƙira da kera sassa na gyare-gyare yana da sauƙi.Burin mu shine mu same ku cikin sauri da inganci.

VDI allura gyare-gyaren saman gama

VDI 3400 Surface Finish (wanda aka fi sani da VDI surface finish) yana nufin ma'auni na rubutu da Verein Deutscher Ingenieure (VDI), Ƙungiyar Injiniya ta Jamus ta kafa.The VDI 3400 surface gama aka yafi sarrafa ta Electrical Discharge Machining (EDM) lokacin da mold machining.Hakanan ana iya yin ta ta hanyar rubutun gargajiya (kamar a cikin SPI).Ko da yake al'ummar Injiniyoyi na Jamus sun tsara ƙa'idodin, ana amfani da su a tsakanin masu yin kayan aiki a ko'ina, ciki har da Arewacin Amirka, Turai, da Asiya.

Ƙimar VDI ta dogara ne akan rashin ƙarfi na saman.Daga hoton, muna ganin nau'o'in nau'i daban-daban na ƙarewar farfajiya tare da bambancin dabi'u na rashin ƙarfi.

| Darajar VDI | Bayani | Aikace-aikace | Tashin ƙasa (Ra µm) |

| 12 | 600 Dutse | Ƙananan sassan goge baki | 0.40 |

| 15 | 400 Dutse | Ƙananan sassan goge baki | 0.56 |

| 18 | Dry Blast Glass Bead | Satin gama | 0.80 |

| 21 | Busasshiyar fashewa # 240 Oxide | Ƙarshe mara kyau | 1.12 |

| 24 | Busasshiyar fashewa # 240 Oxide | Ƙarshe mara kyau | 1.60 |

| 27 | Busasshiyar fashewa # 240 Oxide | Ƙarshe mara kyau | 2.24 |

| 30 | Busasshiyar fashewa # 24 Oxide | Ƙarshe mara kyau | 3.15 |

| 33 | Busasshiyar fashewa # 24 Oxide | Ƙarshe mara kyau | 4.50 |

| 36 | Busasshiyar fashewa # 24 Oxide | Ƙarshe mara kyau | 6.30 |

| 39 | Busasshiyar fashewa # 24 Oxide | Ƙarshe mara kyau | 9.00 |

| 42 | Busasshiyar fashewa # 24 Oxide | Ƙarshe mara kyau | 12.50 |

| 45 | Busasshiyar fashewa # 24 Oxide | Ƙarshe mara kyau | 18.00 |

Kammalawa

Daga cikin nau'ikan nau'ikan nau'ikan allura guda biyu na gamawar farfajiyar allura, matakin SPI A da B ana ɗaukar su mafi santsi tare da ƙarancin ƙasa kuma sun fi tsada.Ganin cewa, daga mahangar rashin ƙarfi, VDI 12, mafi ingancin VDI, yayi daidai da darajar SPI C.

Babu wanda ya taɓa cewa ƙira da kera sassa na gyare-gyare yana da sauƙi.Burin mu shine mu same ku cikin sauri da inganci.

Yadda za a zabi da dace allura gyare-gyaren surface gama?

Zaɓi saman gyare-gyaren allura ta la'akari da aikin sashi, kayan da ake amfani da su, da buƙatun gani.Yawancin nau'ikan alluran filastik na yau da kullun na iya samun nau'ikan ƙarewar ƙasa iri-iri.

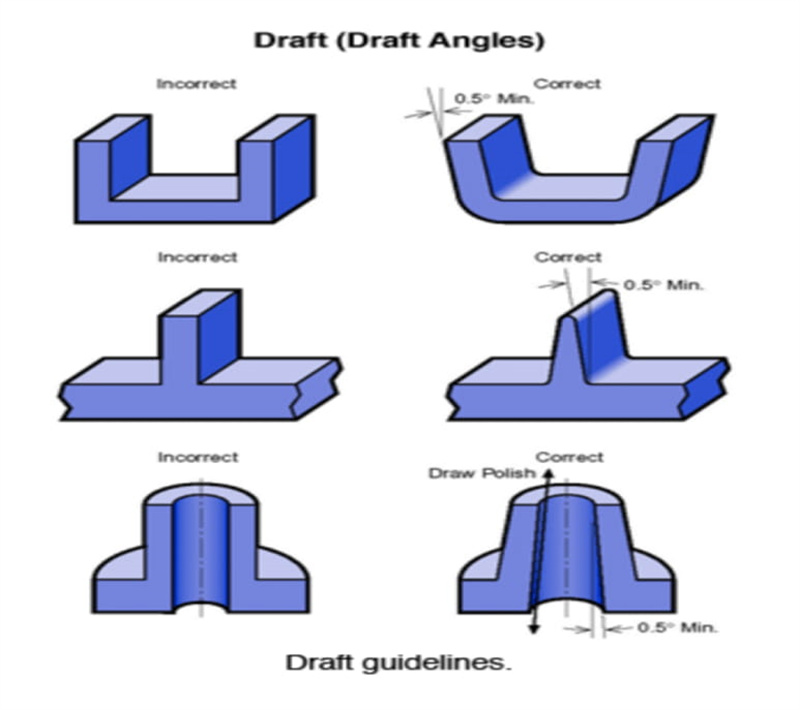

Dole ne a kafa zaɓin ƙarewar saman a farkon ƙirar ƙirar ƙirar samfur saboda saman yana ba da zaɓin zaɓin abu da kusurwar daftarin, yana tasiri farashin kayan aiki.Misali, darasi ko ƙera rubutu yana buƙatar mafi mahimmancin daftarin kusurwa ta yadda za a iya fitar da ɓangaren daga ƙera.

Don haka menene manyan abubuwan da za a yi la'akari da su lokacin zabar ƙarshen farfajiya don gyare-gyaren allura?

Gloss finish Grade A (Madogararsa:Abokin ciniki na Amurka XR)

Kudin kayan aiki

Ƙarshen saman da kayan suna tasiri sosai ga ƙirar kayan aiki da farashi, don haka la'akari da kimanta aikin dangane da farfajiya da wuri akan ƙirar ƙirar.Idan ƙarewar saman yana da mahimmanci ga aikinsa, yi la'akari da ƙarewar saman a matakan ra'ayi na ƙirar samfurin.

Yawancin sassa na aikin gyaran allura an sarrafa su ta atomatik, amma goge goge banda.Sai kawai mafi sauƙi na siffofi waɗanda za a iya goge su ta atomatik.Masu aikin goge baki yanzu suna da ingantattun kayan aiki da kayan aiki da su, amma tsarin ya kasance mai fa'ida.

Tsari kusurwa

Yawancin Sassa Suna Bukatar Daftarin Kungiya na 1½ zuwa Digiri 2

Wannan ƙa'idar babban yatsa ce wacce ta shafi sassa da aka ƙera tare da zurfin har zuwa inci 2.Tare da wannan girman, daftarin kusan digiri 1½ ya isa don sauƙin sakin sassa daga ƙirar.Wannan yana taimakawa wajen hana lalacewa ga sassan lokacin da kayan thermoplastic ya ragu.

Mold kayan aiki kayan aiki

Kayan aikin ƙira yana tasiri sosai akan santsin gyare-gyaren allura.Ana iya yin gyare-gyare daga ƙarfe daban-daban, kodayake ƙarfe da aluminum sun fi shahara.Tasirin waɗannan karafa biyu akan abubuwan da aka ƙera na filastik sun bambanta sosai.

Gabaɗaya, ƙarfe na kayan aiki mai ƙarfi na iya samar da ƙarancin filastik mai santsi idan aka kwatanta da kayan aikin gami na aluminum.Don haka la'akari da gyare-gyaren ƙarfe idan guntuwar suna da aikin ƙaya wanda ke buƙatar ƙananan matakin roughness.

Kayan gyare-gyare

Akwai nau'ikan robobin gyare-gyaren allura don rufe kowane nau'in sassa da ayyuka.Duk da haka, ba duk robobi ba ne ke iya cimma daidaitaccen farfajiyar gyare-gyaren allura.Wasu polymers sun fi dacewa da ƙarewa mai santsi, yayin da wasu sun fi dacewa da roughening sama don ƙarin rubutu.

Halayen sinadarai da na zahiri sun bambanta tsakanin kayan gyare-gyaren allura.Narkar da zafin jiki, alal misali, muhimmin abu ne a cikin ƙarfin abu don ba da takamaiman ingancin saman.Additives kuma suna da tasiri akan sakamakon da aka kammala.A sakamakon haka, yana da mahimmanci don kimanta kayan daban-daban kafin yanke shawara akan nau'in saman.

Bugu da ƙari, abubuwan da ake ƙara abubuwa kamar filler da pigments na iya yin tasiri ga ƙarshen abin da aka ƙera.Teburan da ke cikin sashe na gaba suna kwatanta dacewar kayan aikin allura da yawa don ƙayyadaddun ƙayyadaddun ƙayyadaddun SPI.

Dace da kayan aiki don Grade SPI-A surface gama

| Kayan abu | A-1 | A-2 | A-3 |

| ABS | Matsakaicin | Matsakaicin | Yayi kyau |

| Polypropylene (PP) | Ba a ba da shawarar ba | Matsakaicin | Matsakaicin |

| Polystyrene (PS) | Matsakaicin | Matsakaicin | Yayi kyau |

| HDPE | Ba a ba da shawarar ba | Matsakaicin | Matsakaicin |

| Nailan | Matsakaicin | Matsakaicin | Yayi kyau |

| Polycarbonate (PC) | Matsakaicin | Yayi kyau | Madalla |

| Polyurethane (TPU) | Ba a ba da shawarar ba | Ba a ba da shawarar ba | Ba a ba da shawarar ba |

| Acrylic | Madalla | Madalla | Madalla |

Material dacewa ga Grade SPI-B surface gama

| Kayan abu | B-1 | B-2 | B-3 |

| ABS | Yayi kyau | Yayi kyau | Madalla |

| Polypropylene (PP) | Yayi kyau | Yayi kyau | Madalla |

| Polystyrene (PS) | Madalla | Madalla | Madalla |

| HDPE | Yayi kyau | Yayi kyau | Madalla |

| Nailan | Yayi kyau | Madalla | Madalla |

| Polycarbonate (PC) | Yayi kyau | Yayi kyau | Matsakaicin |

| Polyurethane (TPU) | Ba a ba da shawarar ba | Matsakaicin | Matsakaicin |

| Acrylic | Yayi kyau | Yayi kyau | Yayi kyau |

Material dacewa ga Grade SPI-C surface gama

| Kayan abu | C-1 | C-2 | C-3 |

| ABS | Madalla | Madalla | Madalla |

| Polypropylene (PP) | Madalla | Madalla | Madalla |

| Polystyrene (PS) | Madalla | Madalla | Madalla |

| HDPE | Madalla | Madalla | Madalla |

| Nailan | Madalla | Madalla | Madalla |

| Polycarbonate (PC) | Matsakaicin | Ba a ba da shawarar ba | Ba a ba da shawarar ba |

| Polyurethane (TPU) | Yayi kyau | Yayi kyau | Yayi kyau |

| Acrylic | Yayi kyau | Yayi kyau | Yayi kyau |

Material dacewa ga Grade SPI-D saman gama

| Kayan abu | D-1 | D-2 | D-3 |

| ABS | Madalla | Madalla | Yayi kyau |

| Polypropylene (PP) | Madalla | Madalla | Madalla |

| Polystyrene (PS) | Madalla | Madalla | Yayi kyau |

| HDPE | Madalla | Madalla | Madalla |

| Nailan | Madalla | Madalla | Yayi kyau |

| Polycarbonate (PC) | Madalla | Ba a ba da shawarar ba | Ba a ba da shawarar ba |

| Polyurethane (TPU) | Madalla | Madalla | Yayi kyau |

| Acrylic | Matsakaicin | Matsakaicin | Matsakaicin |

Sigar ƙira

Gudun allura da zafin jiki suna shafar ƙarewar ƙasa saboda wasu 'yan dalilai.Lokacin da kuka haɗu da saurin allura da sauri tare da yanayin zafi mafi girma ko narke, sakamakon zai inganta mai sheki ko santsi na ɓangaren ɓangaren.A haƙiƙanin gaskiya, saurin allura da sauri yana inganta ɗaukacin sheki da santsi.Bugu da ƙari, cike da sauri na kogon ƙira na iya haifar da ƙarancin layukan walda da ingantacciyar kyawawa don ɓangaren ku.

Yanke shawarar ƙarewar wani yanki babban abin la'akari ne a cikin haɓakar samfuran gabaɗaya kuma yakamata a yi la'akari da shi yayin tsarin ƙira don cimma sakamakon da ake so.Shin kun yi la'akari da ƙarshen amfani da sashin gyare-gyaren allurar ku?

Bari Xiamen Ruicheng ya taimaka muku yanke shawara kan ƙarewar saman da ke haɓaka ƙaya da ayyukan ɓangarenku.

Lokacin aikawa: Mayu-22-2023