Ruicheng kwararre ne a cikin kera na'urorin gyare-gyaren allura.Ingantattun hanyoyin gyare-gyaren alluranmu masu inganci suna ba mu damar samfuran samfuran inganci masu inganci kuma zaku iya lissafin aikin don keɓance samfuran filastik na kanku.Muna da damar da za mu iya biyan duk buƙatun ɓangaren masana'antu na filastik dangane da kayan, girma, siffofi, haƙuri, da sauransu.

Common masana'antu roba samfurin

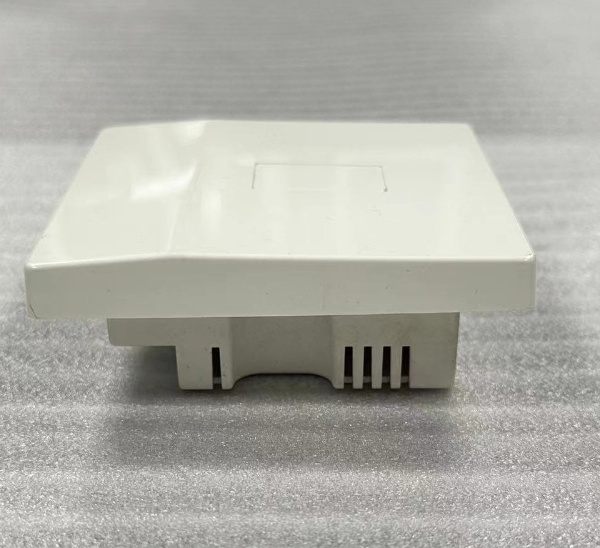

Wannan samarwa shine Madaidaicin Smart WIFI Touch Light Canja gidaje wanda sassa na filastik masana'antu ke yi kuma ya dace da sabon ƙa'idodin Amurka.

Sassan Filastik na Masana'antu na Musamman tare da ingantaccen ruwa da juriya na UV, wanda ke sa wannan samfurin yayi aiki da kyau a yanayin waje.

An yi shi da kayan filastik budurwowi 100%, za mu gudanar da ingantaccen kulawa mai inganci yayin aikin gyaran allura, da gudanar da ingantattun ingantattun abubuwa da taro a lokaci guda.A ƙarshe, za mu isar muku da shi a cikin marufi mai kyau na aminci.

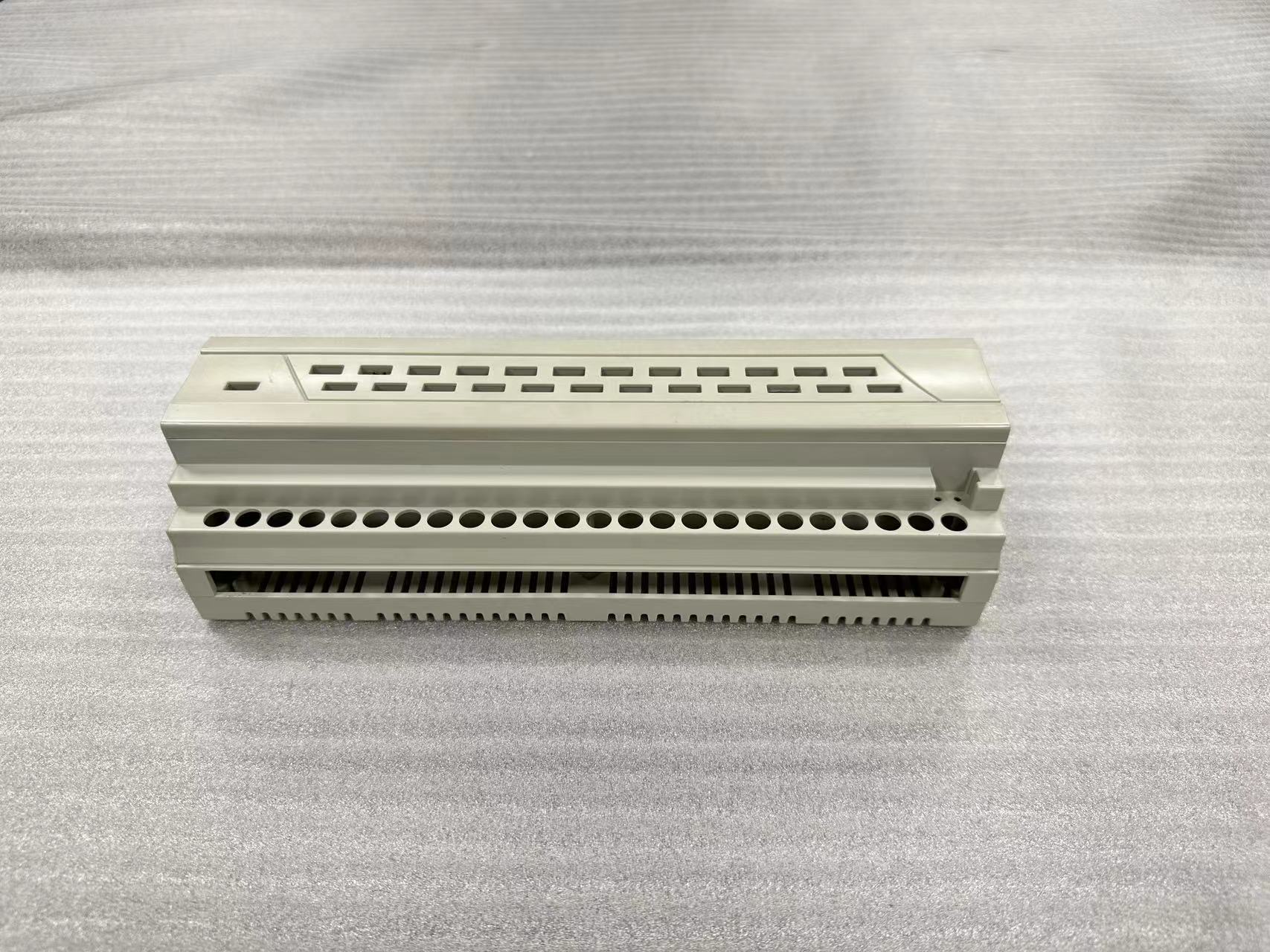

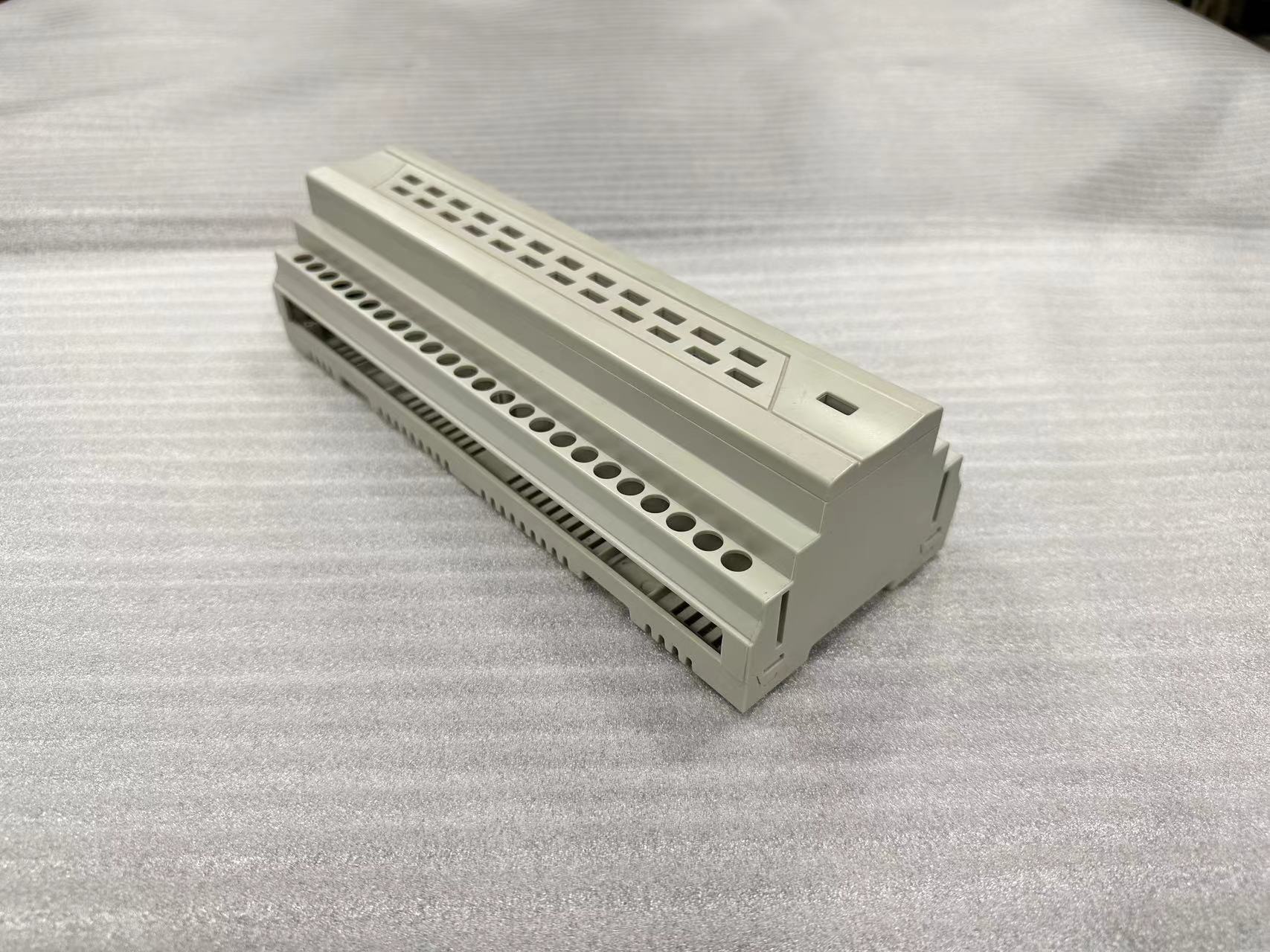

4.Plastic Overmold Insert Connector

Wannan keɓantaccen mai haɗa cajin masana'antu ya dace da tallafin na'urar lantarki.Zai iya ba da garantin shigarwa don kayan aikin ku kuma ya sa ya dace da ku don amfani.

Wani abu za ku iya zaɓar don yin samfurin filastik masana'antu

ABS:

Acrylonitrile Butadiene Styrene (ABS) wani thermoplastic ne wanda aka halicce shi ta hanyar amfani da emulsion.Tare da Ƙarfinsa, mai sauƙi, ƙananan ƙwayar ƙwayar cuta (m tolerances), juriya na sinadarai, ƙarfin lantarki, ta halitta opaque, ƙananan / matsakaicin farashi.

PA66:

PA66 yana daya daga cikin nailan, yana da hali iri ɗaya da nailan, yawanci ana amfani da shi a cikin hannaye, levers, ƙananan gidaje, zip dagears, bushings.

PC

PC yana da wuyar gaske tare da juriya na zafin jiki da kwanciyar hankali mai girma, ana iya yin shi a bayyane amma cikin farashi mai yawa.

PP

PP yana cikin nauyi mai nauyi tare da juriya mai zafi, babban juriya na sinadarai, juriya mai karewa da bayyanar waxy na halitta wanda ke da tauri kuma mai kauri cikin ƙarancin farashi.

TPU:

TPU wani abu ne na roba tare da kyakkyawan juriya ga mai, mai, da abrasion.

Common tsari na masana'antu filastik samfurin

Yin gyare-gyaren allura shine tsarin masana'anta da ake amfani da shi don yawan samar da sassan filastik iri ɗaya.Hanya ce ta allurar filastik inda aka saka robobin da aka narkar da su a cikin wani gyaggyarawa don samar da wani sashi a cikin siffar kogon gyaggyarawa, ƙirƙirar wakilcin zahiri na sassan filastik da aka kera.

Yin amfani da fasahar gyare-gyaren allura don samar da samfuran masana'antu na iya cimma yawan samarwa, wanda zai iya rage farashi ga kamfanoni, rage lokutan isar da masu amfani, da samar da kayayyaki masu inganci.

Bugu da ƙari, sassan alluran da aka ƙera ta hanyar allura suna da kyakkyawan kwanciyar hankali kuma ana iya sake yin amfani da kayan tarkacensu, suna taimakawa wajen kawar da sharar gida.

Overmolding

Overmolding wani tsari ne na masana'anta wanda aka ƙera ɗaya (polymer) ko jefawa akan wani abu mai yuwuwar haɗaɗɗiya, ƙarfe, ko polymer a yanayi.Sakamakon abu guda ɗaya ne, haɗaɗɗen sassa biyu waɗanda gabaɗaya suna da ayyuka daban-daban a cikin ɓangaren da aka haɗa.Aikace-aikacen wannan tsari akan sassa masana'antu na filastik yana da yawa.Silicone yawanci ana lullube shi ne akan sassa na filastik don hana zamewa, kamar buroshin hakori, guduma, na'urorin lantarki, da sauransu. Idan an shafa shi a kan gidaje na kayan lantarki, yawanci don rufewa ne.

Yin gyare-gyare da gyare-gyaren allura ainihin matakai iri ɗaya ne da ake amfani da su don ƙirƙirar sassa na filastik (gaba ɗaya).Sun bambanta kawai a cikin cewa tsarin overmolding shine aiki na biyu.

Da farko kafin mu fara, muna buƙatar ku aiko mana da zane da buƙatun 3d.Kwararrun za su bincika wannan aikin, su kimanta tsarinsa da girmansa don tattaunawa kuma suyi la'akari da yadda za'a tsara ƙirar (kamar ƙofar allura, fil, daftarin kusurwa da sauransu).

Na biyu, ma'aikacin mu zai lissafta yanayin samfurin ku don saita injin allura.Lokacin da kayan aiki ya rufe, yana nuna farkon zagayen gyaran allura.

Za a bushe granules na polymer kuma a sanya su a cikin hopper, sannan a ciyar da su a cikin ganga, inda ake zafi lokaci guda, gauraye kuma a matsar da su zuwa ga ƙirƙira ta hanyar maɓalli mai mahimmanci.An inganta tsarin lissafi na dunƙule da ganga don taimakawa haɓaka matsa lamba zuwa matakan da suka dace da narke kayan.

Bayan an cika ramin ƙira da filastik, dole ne a bar shi ya yi sanyi.Ruwa yana zagayawa yawanci a matsayin babbar hanyar yin zafin jiki akai-akai yayin da kayan ke taurare.

Lokacin da abu ya kwantar da hankali, yana sake ƙarfafawa kuma ya ɗauki siffar mold.A ƙarshe, ƙirar ta buɗe kuma ana fitar da ƙaƙƙarfan ɓangaren ta fitattun masu fitar da su.Mold sa'an nan kuma rufe da tsari maimaita.

Za a tattara samfuran da aka gama ta amfani da jakar filastik kuma a saka su cikin kwali.Idan kuna da buƙatun marufi na musamman, Hakanan za'a iya daidaita mu bisa ga bukatun abokan ciniki .Don haka kowane samfurin za'a kawo shi cikin yanayi mai kyau.

Don ƙarin koyo game da aikin allurar filastiksauran masana'antu samfurinza ka iya tuntuɓar muƙungiyar tallace-tallace don tattauna aikace-aikacenku na musamman.

Lokacin aikawa: Afrilu-15-2024