Vacuum Casting

Vacuum simintin gyare-gyare kuma ana kiransa simintin urethane, a matsayin babban tsari na masana'anta wanda zai iya yin sassa masu wuya da taushi.Tare da gogewa fiye da shekaru 20 a cikin wannan filin, Ruicheng sun sami damar ɗaukar duk buƙatun ku don yin simintin gyaran fuska da gyare-gyaren silicone.

Tuntube mu don samun farashin siliki gyare-gyare.

Menene Vacuum Casting?

Vacuum simintin gyare-gyare a matsayin fasaha na masana'antu wanda ke da fa'idodi na rage farashin ci gaba, ana amfani da lokacin jagora mai sauri a cikin samar da ƙananan batches.

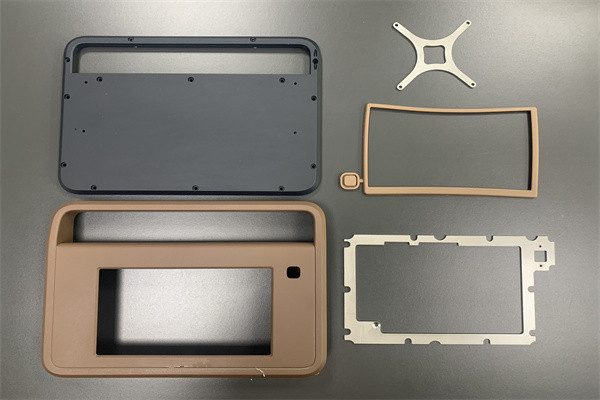

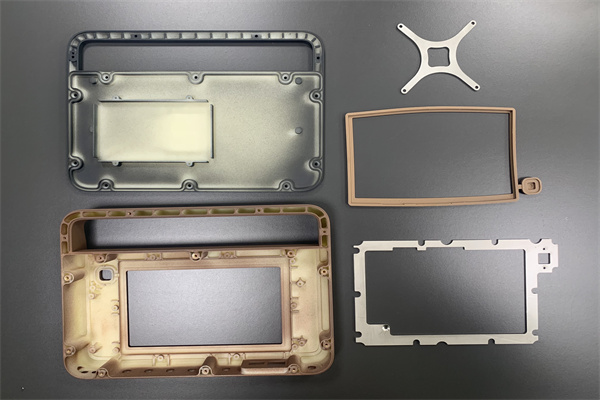

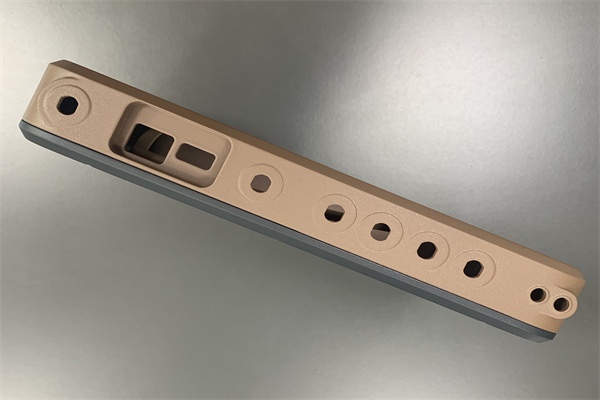

A tsari fara da wani samfurin da aka yi ta 3D bugu ko CNC inji yin silicone mold a cikin injin jihar, da kuma amfani da kayan sun yi kama da ABS, acrylic, PC, PA, taushi roba (da taurin iya zama gabar A 30-90) da kuma sauran kayan don simintin gyare-gyare, don haɗa samfuran iri ɗaya.

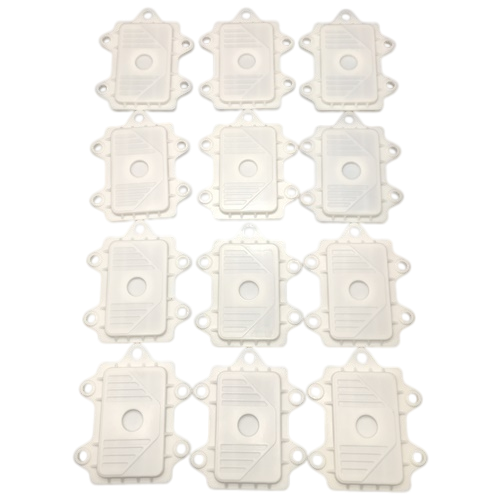

A al'ada, ana iya amfani da ƙwayar silicone guda ɗaya don sau 20 sannan kuma a goge mold ɗin.Idan kana buƙatar ƙarin sassa, wanda dole ne ya yi sabon siliki mold.

Fa'idodin Vacuum Casting

1.Rashin tsada

Farashin siliki mold ne da yawa ƙasa da allura mold, shi yawanci amfani da kananan batches samar.

2.Fast lokacin jagora

Yana ɗaukar kwanaki 7 ko ƙasa da haka don yin ƙananan sassa masu sauƙi

3.Wide zaɓi na kayan aiki

Abubuwan resin da aka yi amfani da su don gyare-gyaren silicone sun fi zaɓaɓɓu sosai, daga taushi da sassauƙa zuwa m da juriya.

4. Maimaituwa

Ana iya amfani da nau'in siliki ɗaya a kusa da sau 20, dangane da tsari da girman ƙira mai sauƙi ko rikitarwa

5.Good simulation yi

Silicone molds iya yin sassa tare da hadaddun tsarin da lafiya alamu.

Tsarin Simintin Wuta

| Mataki 1: Samfuran Samfura | Kafin yin gyare-gyaren silicone, muna buƙatar amfani da zane na CAD don yin samfurin ta hanyar bugu na 3D ko fasahar injin CNC. |

| Mataki 2: Silicone mold Yin | Cika ruwan siliki a cikin akwatin simintin , zafi akwatin har sai ya warke sosai sannan a saka a cikin tanda don warkewa.Cika da ƙarin ruwa na silicone wanda shima yana zafi kuma an warke.Da zarar ya bushe, yanke buɗaɗɗen siliki kuma cire samfurin. |

| Mataki na 3: Yi sassan | A ƙarshe, zuba resin a cikin rami mara kyau don ƙirƙirar kwafin ainihin.Ana iya amfani da mold don sake zagayowar samarwa na gaba. |

Ƙayyadaddun Fasaha na Simintin Kayan Wuta

| Lokacin jagora | 7-10 kwanaki |

| Hakuri | + - 0.05 mm |

| Mafi ƙarancin kauri na bango | aƙalla 1mm (dangane da zane na abokin ciniki) |

| Launi | Kamar yadda buƙatun abokin ciniki |

| Gama | rubutu ko m surface gama |

Vacuum Casting FAQ

*Waɗanne abubuwa ne za a iya amfani da su don yin simintin ruwa?

Akwai da yawa zažužžukan ga kayan zabi, kamar ABS, acrylic, PC, PP, PE, PA, POM, PMMA, PVC, taushi roba (taurin iya zama shoreA 30-90), da dai sauransu, amma kayan ne daban-daban daga kayan abin da ake amfani da su don gyaran allura, waɗanda ba za su iya cimma aikin ƙirar allura ba.

*Me ya sa za a zaɓi yin simintin gyaran fuska?

Idan ba ku da tabbacin ko ƙirar ku za ta sami manyan canje-canje kafin matsawa zuwa gyare-gyaren allura, ƙwanƙwasa ƙwanƙwasa hanya ce mai sauri da tattalin arziki don yin ƙaramin tsari don tabbatar da ƙirar ku.

*Yaya ake rike da siliki?

Silicone mold ya bambanta da nau'in allurar karfe, wanda za a shafe kusan sau 20 samarwa, har sai ba za a iya amfani da su ba, za mu zubar da su.

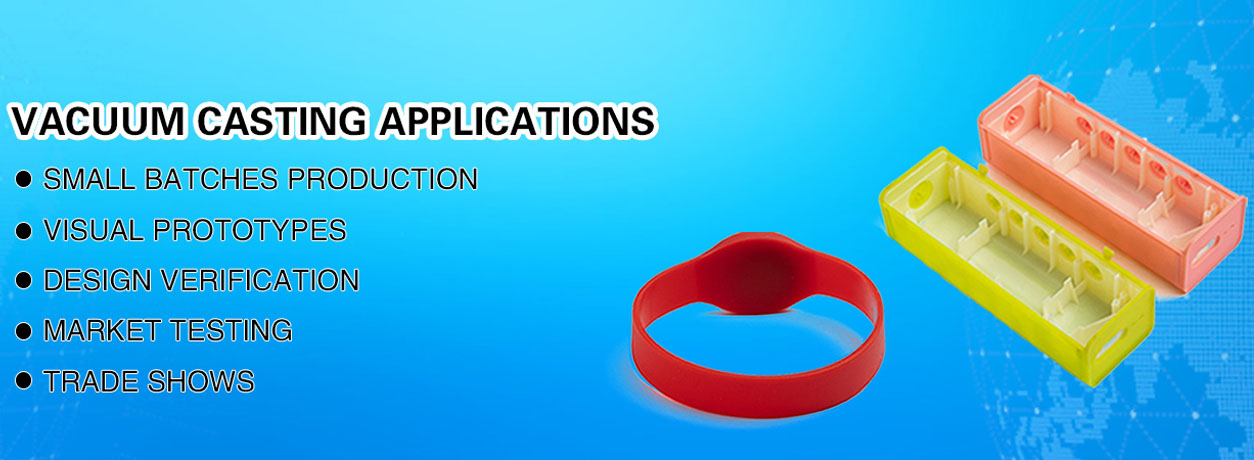

Yadda Vacuum Casting ke Amfani da Ayyukanku