1.Coating Jiyya: Daya daga cikin na kowa surface jiyya hanyoyin for hardware ne shafi jiyya, kamar galvanizing, nickel plating, da kuma chroming.Rubutun suna ba da kariya mai kariya akan saman karfe, haɓaka juriya na lalata da inganta bayyanar.Rubutun kuma na iya ƙara ƙarfi da juriya na ƙarfe.

2.Painting Jiyya: Zane-zane hanya ce ta gama gari don kayan aiki, inda ake amfani da murfin kariya ta hanyar fesa fenti ko fenti akan saman ƙarfe.Zane na iya samar da launuka daban-daban da tasiri, inganta bayyanar da samar da ayyuka kamar juriya na lalata da juriya.

3.Heat Jiyya: Maganin zafi ya haɗa da canza tsarin da kaddarorin kayan aiki ta hanyar dumama da sarrafa tsarin sanyaya.Hanyoyin magance zafi na gama gari sun haɗa da annealing, quenching, da tempering.Maganin zafi na iya inganta taurin, ƙarfi, da juriya na lalata kayan aikin don biyan takamaiman buƙatun aikace-aikacen.

4.Polishing Jiyya: Gogewa shine tsari na sanya saman karfe ya zama santsi da sheki ta hanyar inji ko hanyoyin sinadarai.goge goge na iya cire lahani, oxides, da gurɓatawa daga saman kayan masarufi, haɓaka kamanni da ingancin taɓawa.

5.Brushing: Brushing ne na kowa karfe karewa hanya amfani da farko don canja bayyanar da rubutu na karafa.Ana shafa shi akan karafa iri-iri kamar bakin karfe, aluminum da tagulla.Yin gogewa yana ba da kamanni na musamman ga ƙarfe ta hanyar injiniyoyi ko sinadarai don yin la'akari da saman ƙarfen don samar da nau'i mai layi ko tarkace.

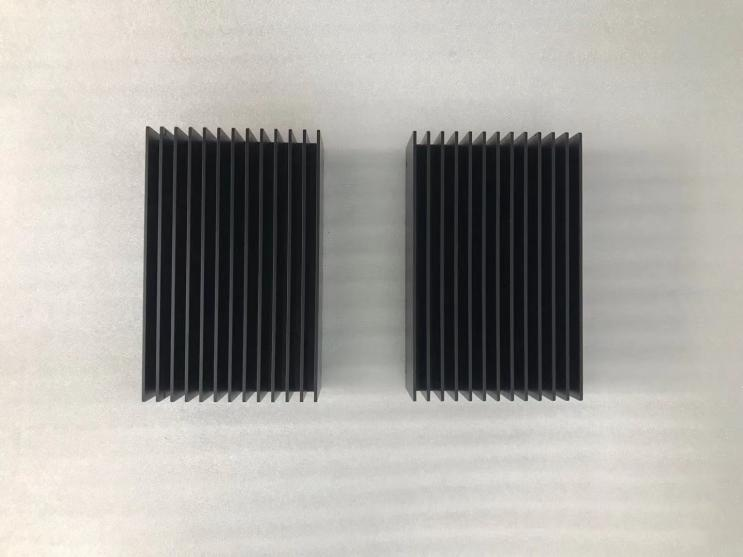

6.Anodizing: Anodizing ne na kowa surface jiyya Hanyar amfani ga aluminum da kuma gami.Ya ƙunshi samuwar wani Layer oxide akan saman aluminum ta hanyar tsarin lantarki, yana haɓaka juriya na lalata, taurinsa, da juriya.

7.Laser engraving: Laser engraving wani tsari ne da ke amfani da fasahar Laser don tsara saman wani abu.Yana vaporizes ko oxidizes abu a saman wani abu ta hanyar mayar da hankali da kuma haskakawa na wani babban makamashi Laser katako, haifar da wani tsari, rubutu ko hoto a cikin zurfi ko m taimako.

8.Blackening:Blackening magani ne na saman da aka saba amfani da shi don samfuran ƙarfe, musamman kayan ƙarfe.Ana amfani da shi don duhun launi da ƙara juriya na lalata ta hanyar samar da baƙar fata oxide a saman saman ƙarfe.

9.Dacromet (Dacro): Dacromet (Dacro) sunan kasuwanci ne don ƙarewar ƙarfe da murfin lalata.Yana da wani ci-gaba anticorrosive shafi fasaha da ake amfani da farko don kare karfe da baƙin ƙarfe kayayyakin daga lalata da hadawan abu da iskar shaka.

Rubutun Dacromet yawanci sun haɗa da abubuwa masu zuwa:

Fure-fure mara-kyau: Wannan shi ne ginshiƙi na rufin Dacromet, wanda ba ya ƙunshi mahaɗan chromium masu cutarwa.Babban aikin farko shine samar da kyakkyawar mannewa da juriya na lalata yayin samar da tushe mai tushe don saman gashi.

Rufe Matsakaici mai jure lalata: Wannan shine maɓalli mai mahimmanci na rufin Dacromet.Matsakaicin Layer yana ƙunshe da nau'ikan masu hana ɓarna da ɓarna masu jurewa waɗanda ke hana lalata da iskar shaka na saman karfe.

Rufin Kwayoyin Halitta: Wannan shi ne mafi girman Layer na rufin Dacromet kuma yawanci shine murfin guduro na kwayoyin halitta.Ba wai kawai yana samar da launi da tasirin kayan ado ba, amma har ma yana ƙara ƙarfin ƙarfi da juriya na sutura.

10.Yashi: fashewar yashi, wanda kuma aka sani da tsaftacewa yashi, goge yashi, ko sandblasting huhu, wata dabara ce ta shiri ta gama gari da ake amfani da ita don tsaftacewa, rarrabuwa, ko inganta yanayin saman abu.

Lokacin zabar maganin saman don ƙarfe, abubuwa da yawa suna buƙatar la'akari:

Makasudi da buƙatun: Na farko, ƙayyade takamaiman manufar ku da buƙatun ku don jiyya na saman ƙarfe.Shin kuna nufin kare karfe daga lalata da iskar shaka, inganta kayan kwalliya, ƙara tasirin ado, ko haɓaka mannewa shafi?Hanyoyin jiyya daban-daban suna haifar da sakamako daban-daban bisa dalilai daban-daban da buƙatu.

Nau'in kayan aiki: Yi la'akari da nau'i da halayen karfe.Ƙarfe daban-daban, irin su ƙarfe, aluminum, jan ƙarfe, da sauransu, na iya samun sauye-sauye daban-daban zuwa hanyoyin jiyya daban-daban.Wasu karafa na iya zama mafi kusantar lalata, yayin da wasu na iya buƙatar hanyoyin jiyya na musamman don haɓaka mannewa.

Yanayin muhalli: Yi la'akari da yanayin muhallin da samfurin ƙarfe zai fallasa.Idan ƙarfen zai kasance yana fallasa zuwa yanayi mai ɗanɗano, acidic, ko gurɓataccen yanayi, zaɓin hanyar jiyya mai kyau tare da kyakkyawan juriya na lalata yana da mahimmanci.Idan za a yi amfani da ƙarfe a waje, juriya na yanayi da juriya UV su ma abubuwan da za a yi la'akari da su.

Kasafin kuɗi da farashi: Hanyoyi daban-daban na jiyya na sama na iya samun bambance-bambancen farashi da matsalolin aiwatarwa.Yi la'akari da kasafin kuɗin ku da albarkatun da ake da su don zaɓar hanyar da ta dace da ƙarfin kuɗin ku.

Yiwuwa da aiki: Yi la'akari da yuwuwar da aiki na hanyar da aka zaɓa na jiyya ta saman.Wasu hanyoyin na iya buƙatar kayan aiki na musamman da ƙwarewa, yayin da wasu na iya zama mafi sauƙi kuma mafi sauƙi.Tabbatar cewa kuna da kayan aiki masu mahimmanci, ƙwarewa, da albarkatu, ko kuna iya samun taimako na ƙwararru.

Idan akai la'akari da abubuwan da ke sama, zaku iya zaɓar daga nau'ikan hanyoyin jiyya na ƙarfe masu dacewa, gami da sandblasting, electroplating, galvanizing mai zafi, anodizing, murfin foda, da sauransu.Idan ba ku da tabbacin wace hanya ce ta fi dacewa da yanayin ku, kuna iya tuntuɓar mu.Xiamen Ruicheng ya yi kowane nau'i na maganin saman karfe don yawancin abokan aikinmu kuma ya sami kyakkyawan bita.Ƙwarewarmu da iliminmu na iya ba ku cikakken shawara dangane da takamaiman bukatunku.

Lokacin aikawa: Fabrairu-23-2024