A matsayin ɗaya daga cikin hanyoyin gargajiya, tambari yana shahara sosai a cikin masana'antar keɓancewa.Musamman ga masana'antun, tsarin stamping na iya kawo babbar fa'ida.Idan kana son sanin yadda ake samun hakan, da fatan za a ci gaba da karanta wannan labarin.

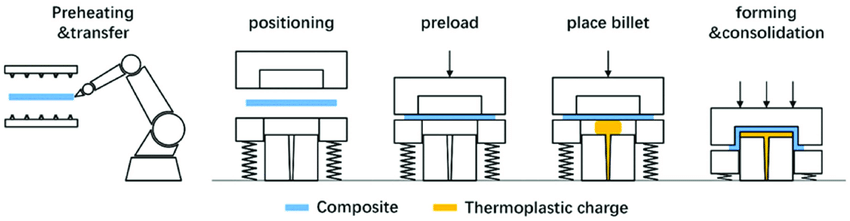

Stamping-wanda kuma ake kira latsawa - ya haɗa da sanya ƙarfe mai lebur, a cikin ko dai coil ko babu komai, cikin latsa mai tambari.A cikin latsawa, kayan aiki da saman mutu sun samar da ƙarfe a cikin siffar da ake so.Yin naushi, ɓata lokaci, lankwasawa, ƙira, ƙwaƙƙwara, da flanging duk dabarun yin tambari ne da ake amfani da su don siffanta ƙarfe.

Kafin a iya samar da kayan, ƙwararrun ƙwararru dole ne su tsara kayan aikin ta hanyar fasahar injiniya ta CAD/CAM.Waɗannan ƙirar dole ne su kasance daidai gwargwadon yuwuwa don tabbatar da kowane naushi da lanƙwasa suna kula da sharewa da kyau kuma, don haka, mafi kyawun sashi.Samfurin 3D na kayan aiki guda ɗaya zai iya ƙunsar ɗaruruwan sassa, don haka tsarin ƙirar galibi yana da rikitarwa kuma yana ɗaukar lokaci.

Da zarar an kafa ƙirar kayan aiki, mai sana'a na iya amfani da nau'ikan machining, niƙa, waya EDM da sauran ayyukan masana'antu don kammala samar da shi.

1. Barkewa

2.Bugi

3.Zane

4. Zane mai zurfi

5.Lancing

6. Lankwasawa

7. Samuwar

8. Gyaran jiki

9. Tafiya

Amfanin tsarin hatimi na al'ada

Daidaito

Ƙarfe Stamping ya fita daga cikin taron saboda gagarumin madaidaicin maimaitawarsa.Cikakken yanayin wannan tsari yana ba mu damar kera sifofin ƙarfe a cikin mafi rikitarwa siffofin yayin da yiwuwar kuskure ba ta da yawa.

Ƙarfin farashi

Ƙarfe Stamping yana ba da damar raguwa mai mahimmanci na lokacin sarrafawa yayin haɓaka saurin samarwa.Ƙarfe stamping yana rage yawan amfani da inji mai yawa, yawan ma'aikata, da kuma lokacin aiki wanda sakamakon haka yana rage yawan farashin samarwa.Wannan hanyar ita ce cikakke ga kamfanonin da ke buƙatar dubban sassa don oda mai yawa kamar yadda yake ba da damar ajiyar kuɗi akan wasu hanyoyin.

Tsari mai sarrafa kansa da ƙarin ƙima

Lokacin yanke shawara akan aiki mai girma, kuna buƙatar daidaita farashi, inganci, da girma.Ƙarfe stamping yana sauƙaƙa sosai don kammala aikin mai girma saboda tsarin sarrafa kansa.Ba wai kawai tsarin yana sarrafa kansa sosai ba, har ma yana iya haɗa ayyuka na biyu kamar saka kwaya ta atomatik.

Wane tsari na stamping karfe ya dace don aikin ku?

Karfe stamping sanannen tsari ne na masana'antu don haɓaka sassa tare da juriya ta amfani da ƙarfe, kamar ƙarfe, jan ƙarfe, bakin karfe, da aluminum.Kuna iya yin amfani da tambarin ƙarfe don kera samfura a cikin masana'antu daban-daban kamar:

1. Motoci

Yana taka muhimmiyar rawa a cikin masana'antar kera kera motoci - samar da abubuwan haɗin gwiwa kamar sassan jiki, braket, sassan chassis, hawan injin, braket, da abubuwan dakatarwa.Tsarin yana tabbatar da samar da sassauƙan nauyi, ɗorewa, da sassauƙar sauti waɗanda suka dace da aminci mai ƙarfi da buƙatun aiki.

2.Kayan lantarki

A cikin masana'antar lantarki, ana amfani da na'urorin lantarki (masu haɗawa, tashoshi, magudanar zafi, abubuwan kariya, da maɓalli).Tambarin ƙarfe ya ba da damar ƙirƙira madaidaicin sassa masu rikitarwa da ake buƙata don majalissar lantarki tare da tabbatar da ingancin wutar lantarki da dorewa.

Sashe na Tambarin Gidajen Lantarki

3.Kayan gida

Hakanan ana amfani da tsarin sosai wajen kera kayan aikin gida kamar firiji, injin wanki, tanda, da tsarin HVAC.Yana samar da abubuwa kamar fanai, rukunoni, madaukai, da riguna, suna samar da kyawawan kyawawan halaye da mutuncin tsari.

4.Masana'antar Kula da Lafiya

A fannin likitanci, na'urori irin su kayan aikin tiyata, na'urorin da aka sanyawa orthopedic, brackets, da masu haɗawa suma suna da abubuwan da suka yi aikin tambarin ƙarfe wanda ke tabbatar da samar da daidaitattun sassa, bakararre, da ma'auni masu dacewa da mahimmanci ga aikace-aikacen likita.

Idan kuna da wasu ayyuka masu zuwa don yin tambari kuma kuna buƙatar wannan fasaha.

Don Allahtuntube mu!

Za mu iya samar da fasaha na ƙwararru don yin hatimi don taimaka muku.

Lokacin aikawa: Maris 19-2024