A cikin zayyana sassan filastik, kaurin bangon sashin shine ma'auni na farko da za a yi la'akari da shi, kaurin bangon sashin yana ƙayyade kayan aikin injin, bayyanar sashin, ikon allurar sashi da farashi. na bangare.Ana iya cewa zaɓi da zane na kauri na bangon ɓangaren yana ƙayyade nasara ko gazawar ƙirar ɓangaren.

Kaurin bango dole ne ya zama matsakaici

Saboda halaye na kayan filastik da tsarin allura,kaurin bangon sassan filastik dole ne ya kasance cikin kewayon da ya dace, ba ma bakin ciki ba, kuma ba mai kauri ba.

Idan kaurin bango ya yi yawa, Ana allurar sassan lokacin da kwararar juriya, narke filastik yana da wahala a cika dukkan rami, dole ne su zama kayan aikin allura mafi girma don samun saurin cikawa da matsa lamba.

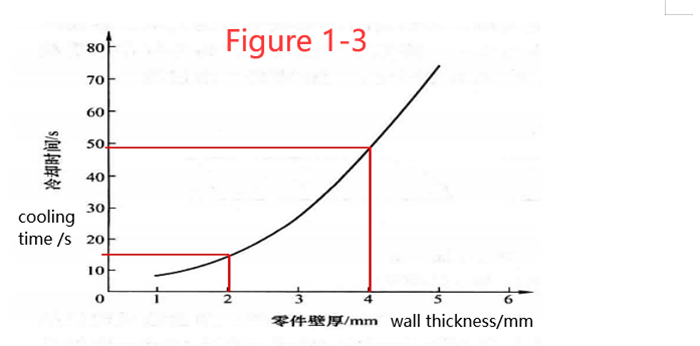

Idan kaurin bango yayi kauri sosai, Ƙarfafa lokacin sanyaya sassa (bisa ga kididdigar, sassan bangon bango ya karu da sau 1, lokacin sanyaya ya karu da sau 4), sassan gyare-gyaren gyare-gyare yana ƙaruwa, ƙananan samar da kayan aiki yana da ƙasa;a lokaci guda, kaurin bango mai kauri yana da sauƙi don haifar da sassa don haifar da raguwa, porosity, warpage da sauran matsalolin inganci.

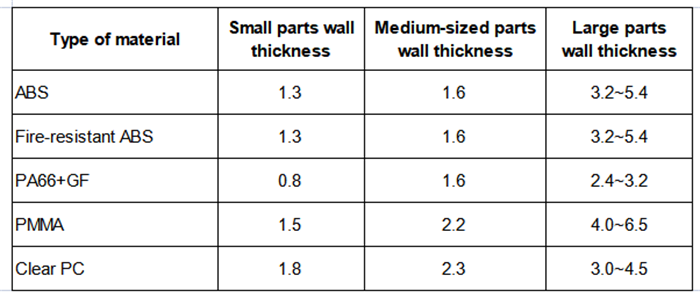

Kayayyakin filastik daban-daban suna da buƙatu daban-daban don kaurin bangon da ya dace na sassan filastik, har ma da masana'antun filastik daban-daban na kayan filastik iri ɗaya na iya samun buƙatun kaurin bango daban-daban.An nuna sassan kayan filastik da aka saba amfani da su na kewayon kauri na bango da ya dace a cikin Tebur 1-1.Lokacin da kaurin bangon sassan filastik kusa da babba da ƙananan iyaka na ƙimar kaurin bangon da ya dace, injiniyan ƙirar samfur ya kamata ya nemi shawara daga masana'anta filastik.

Tebur 1-1 Zaɓin kauri na bango don sassan filastik

(naúrar: mm)

Mahimman abubuwan da ke ƙayyade kaurin bangon ɓangaren filastiks:

1) Ko ƙarfin tsarin sashi ya wadatar.Gabaɗaya magana, ƙaurin bangon kauri, mafi kyawun ƙarfin sashin.Amma kaurin bangon sassan ya wuce wani yanki, saboda raguwa da porosity da sauran matsalolin inganci, haɓaka kaurin bangon sassan zai rage ƙarfin sassan.

2) Bangaren zai iya tsayayya da ƙarfin fitarwa lokacin yin gyare-gyare.Idan sashin ya yi bakin ciki sosai, za a samu nakasu cikin sauki ta hanyar fitar da shi.

3) Iya iya jurewa ƙarfin ƙarfafawa yayin haɗuwa.

4) Lokacin da akwai abubuwan ƙarfe na ƙarfe, ƙarfin da ke kewaye da abin da aka saka ya isa.Ƙarfe na gabaɗaya da ƙaƙƙarfan kayan filastik da ke kewaye ba iri ɗaya ba ne, mai sauƙin samar da ƙarfin damuwa, ƙarancin ƙarfi.

5) Ƙarfin sassa don watsar da tasirin tasirin da aka yi musu.

6) Ko ƙarfin ramin ya isa, ƙarfin ramin yana raguwa cikin sauƙi saboda tasirin alamomin fusion.

7) A cikin gabatarwar saduwa da buƙatun da ke sama, kuma gyare-gyaren allura ba zai haifar da matsalolin inganci ba, bangon kauri na sassa na filastik ya kamata ya zama ƙanƙanta kamar yadda zai yiwu, saboda kauri mai kauri ba zai ƙara ƙimar kayan abu da nauyin nauyi ba. bangaren, amma kuma ya tsawaita zagayowar gyare-gyaren sashi, don haka ƙara farashin samarwa.Hoto 1-3 yana nuna alaƙa tsakanin kauri na bango da lokacin sanyaya don ɓangaren filastik ABS.

Domin tabbatarwa da haɓaka ƙarfin sashi, injiniyoyin ƙirar samfuri sukan zaɓi zaɓin ɓangaren bango mai kauri.

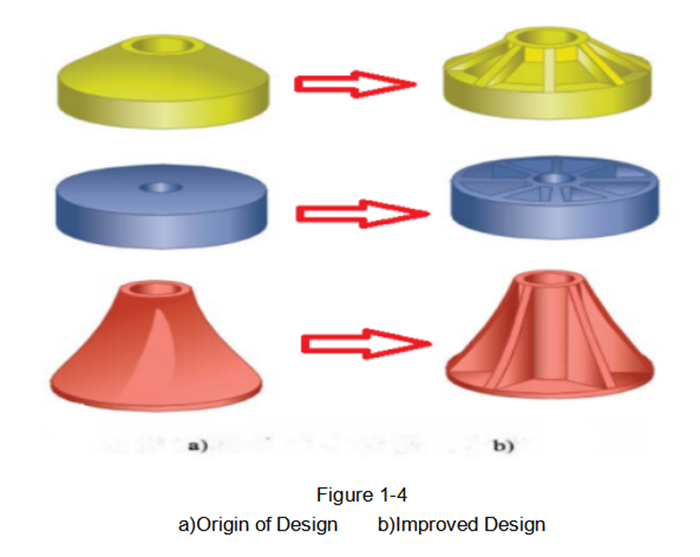

A gaskiya ma, ba shine hanya mafi kyau don tabbatarwa da inganta ƙarfin sashi ta hanyar zabar kauri mai kauri ba.Za a iya inganta ƙarfin sashi ta ƙara ƙarfafawa, zayyana bayanan martaba mai lankwasa ko wavy, da dai sauransu. Wannan ba wai kawai yana rage ɓarnawar ɓangaren ɓangaren ba, amma kuma yana rage lokacin sake zagayowar allura na ɓangaren.

Uniform bango kauri na sassa

Mafi kyawun rarraba kauri na bango na sassa yana cikin kowane ɓangaren giciye na sassan kauri iri ɗaya.Kaurin bango mara daidaituwa na iya haifar da sanyaya mara daidaituwa da raguwar sashin, wanda ke haifar da raguwar ɓangaren ɓangaren, porosity na ciki, yaƙe-yaƙe da nakasar ɓangaren, daidaiton girman yana da wahala don tabbatar da lahani.

Misalan sassa na filastik gama gari tare da ƙirar kaurin bango iri ɗaya ana nuna su a cikin hoto 1-4.

Idan ɓangaren kauri na bango ba zai yiwu ba, to, aƙalla buƙatar tabbatar da cewa ɓangaren bangon bangon bango da bangon bakin ciki a madaidaiciyar canji, don guje wa canje-canje masu kaifi a cikin kauri na bangon.Canje-canje mai sauri a cikin kauri na bangon sassan yana shafar kwararar filastik narke, sauƙin samar da alamun damuwa a bayan filastik, yana shafar bayyanar samfurin;a lokaci guda mai sauƙi don haifar da ƙaddamar da damuwa, rage ƙarfin sassa na filastik, yana da wuya ga sassa don tsayayya da kaya ko tasiri na waje.

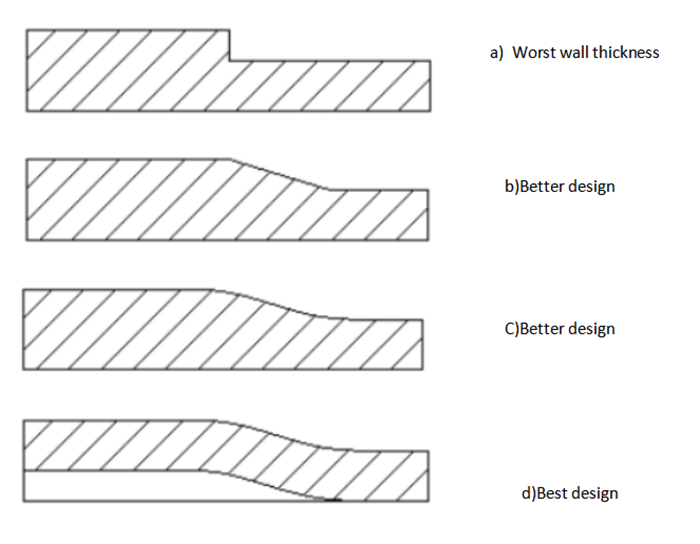

Sashe huɗu na kaurin bango na ƙirar kauri mara daidaituwa kamar yadda aka nuna a hoto 1-5.

An nuna ƙirar bango mafi muni a cikin a), inda akwai canji mai mahimmanci a cikin kauri na bangon ɓangaren;

An nuna mafi kyawun ƙirar bangon bango a cikin Hoto b) da c), kauri na bango a sauye-sauyen bangon bakin ciki na bango, gabaɗaya, tsayin yankin tsaka-tsakin ya ninka sau uku;

An nuna mafi kyawun kauri na bango a d), ba kawai ɓangaren bangon kauri mai santsi ba, amma har ma a cikin ɓangaren bangon bango ta amfani da ƙirar ƙira, ba kawai don tabbatar da cewa ɓangaren ba ya raguwa, amma har ma don tabbatar da ƙarfin ƙarfin. sassan.

Ƙarin Tambayoyi akan kaurin bangon filastik, da fatan za a iya tuntuɓar mu aadmin@chinaruicheng.com.

Sabbin Labaran Abubuwan Gyaran Allurar Filastik

BUKATAR TAIMAKO?

Lokacin aikawa: Dec-22-2022